Can Flexible PCB Boards Be Recycled?

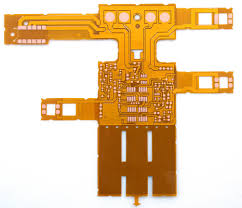

Flexible PCB Boards

There is no doubt that PCBs are important for the electronics industry and that they contain precious metals, base metals and other materials with varying degrees of value. However, many people don’t realize that these materials can cause environmental damage if they are not properly recycled or disposed of.

Once a product completes its operational life, it becomes trash, known as e-waste. This e-waste can be sent to a landfill, where solvents and chemicals can bleed into the soil, or it can be transported to a recycling center. E-waste recycling is an essential part of a sustainable world and should be the goal of any electronic company.

One of the best ways to ensure that your flex circuit is recyclable is to choose the right material. Many different types of flex circuit materials exist, including both rigid and flexible pcb board. Each material has its own set of strengths and weaknesses. To make sure you are choosing the best material for your flex circuit, consider the following factors.

Can Flexible PCB Boards Be Recycled?

PCBs are made of various metal materials, with copper making up the majority. This copper is valuable because it allows electrical conductors to transfer information. Other metals like iron, tin, and zinc are also found in the PCB. Some are even precious metals like gold and silver.

The problem with the old way of recycling a PCB is that the metals need to be separated from the organic residue of the resin and fibreglass. This process is called pyrometallurgy and requires significant amounts of energy to heat and melt the materials. The process emits toxic fumes and smoke that can pollute the environment.

New pyrometallurgical techniques can separate the different metals and other materials from a PCB without using as much energy. These methods can also reduce pollution and save on cost. But despite the improved efficiency, it is still very difficult to recycle a PCB without creating pollution.

A new research project has been developed that uses a reusable polymer to recycle end-of-life PCBs. The polymer can bind the copper to prevent it from oxidizing and provide a solderable surface. The researchers have patented their invention and are working to commercialize it.

It’s essential for a designer to understand how a flex circuit is manufactured. This knowledge can help you minimize design flaws that can be a challenge to repair. For example, a flex circuit’s drill-to-copper distance must be 8 mil or greater to avoid delamination during assembly. It’s also vital to consider whether a flex board should use panel plating, or if pad-only plating is preferable. The latter method has the advantage of higher etch yields, lower stress on the copper traces and better control of impedance. It’s also easier to design for the flex circuit with this construction technique.